Educational

Overview

The educational sector provides instruction and training for students interested in pursuing a career in one of the skilled trades. Some of the most common professions taught at vocational schools include welding, construction, plumbing, pipefitting, electrical work, carpentry, automotive service, sheet metal fabrication and machining.

An education in one of the skilled trades typically takes anywhere from a few months to two years to complete. Career & technical education (CTE) prepares students to either enter the work force after graduation or to become a paid apprentice in their chosen field. The four main skilled trade sectors include construction, industrial/ manufacturing, motive power and service.

Required Applications

Many of the skills taught at vocational schools and technical colleges produce toxins that can seriously harm student health if not properly controlled. Welding, grinding and deburring create toxic smoke, dust and fumes that can lead to a number of severe health conditions including cancer. To protect the health of both students and educators, steps need to be taken to capture welding, grinding and deburring toxins before they contaminate indoor air.

Welding

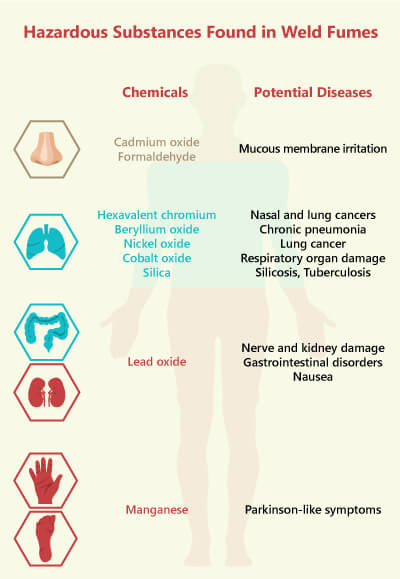

Trade school students pursuing welding certifications run the risk of exposure to toxins that pose serious threats to their health.  The type of contaminant and the resulting illness depend on the type of metal being welded.

The type of contaminant and the resulting illness depend on the type of metal being welded.

Some of the heavy metals and toxins found in welding smoke include: chromium, nickel, arsenic, asbestos, manganese, silica, beryllium, cadmium, nitrogen oxides, phosgene, acrolein, fluorine compounds, carbon monoxide, cobalt, copper, lead, ozone, selenium, and zinc. Both nickel and chromium have been classified as carcinogens while inhaling levels of cadmium can be fatal.

Weld smoke exposure can cause a number of minor symptoms such as respiratory irritation, allergy symptoms, nausea, vomiting, headaches and dizziness. But the list doesn’t end there. Some of the more serious conditions resulting from weld smoke exposure include:

- Chest pain

- Liver and kidney failure

- Birth defects

- Severe nasal and skin ulcerations and lesions

- Respiratory damage

- Lead poisoning

- Nervous system damage

- Pulmonary edema (fluid in lungs)

- Metal fume fever

- Pneumonitis (inflammation of the lungs)

- Reproductive problems

- Emphysema

- Silicosis

- Siderosis

- Lung and nasal cancers

The welding of stainless steel also exposes students to the carcinogen, hexavalent chromium. Besides nasal and lung cancer, hexavalent chromium can cause liver and kidney failure, birth defects, upper abdominal pain and respiratory irritation.

Students that weld with galvanized steel put themselves at risk of developing metal fume fever. An illness with flu-like symptoms such as fever, weakness, fatigue, chills, aches, nausea and chills, metal fume fever usually lasts for no more than a day.

Welding galvanized steel also releases toxic zinc. Inhaling large amounts of zinc over a short period of time can be fatal. Other conditions caused by zinc fumes include:

- Skin, eyes, lungs and mucus membrane irritation

- Difficulty breathing

- Chest pain

- Tightness

- Dermatitis, rashes and chemical burns

Pipefitting

Along with welding, students studying the pipefitting trade  learn skills that can expose them to a number of harmful contaminants. Brazing, soldering, plasma cutting as well as grinding and deburring are common skills pipefitters need to acquire to become proficient in their field. Like weld smoke, the dusts and fumes from these applications can have serious health consequences if left unaddressed.

learn skills that can expose them to a number of harmful contaminants. Brazing, soldering, plasma cutting as well as grinding and deburring are common skills pipefitters need to acquire to become proficient in their field. Like weld smoke, the dusts and fumes from these applications can have serious health consequences if left unaddressed.

Grinding and Deburring

Students learning how to grind come into contact with highly toxic dust and particles if not captured at source. Airborne metal, composite, rubber or fiberglass dust are just some of the contaminants that grinding can produce. Certain metallic dusts like aluminum, titanium and magnesium are combustible and pose a risk of fire or explosion if not handled properly.

While grinding particles frequently cause conditions that affect the lungs, they also can have a negative impact on the liver, kidneys and even the brain.

Common health problems associated with exposure to grinding dusts are nausea and vomiting, respiratory irritation, headaches and dizziness as well as irritated eyes, nose and throat. Some of the more serious conditions include:

- Black lung

- Pneumoconiosis (also called “dusty lung”)

- Silicosis

- Tuberculosis

- Kidney disease

- Lung cancer

- Chest pain

- Respiratory damage

- Difficulty breathing

- Excess fluid in the lungs

- Lead poisoning

- Nervous system damage

When it comes to grinding and deburring, you want an effective capture-at-source or ambient ventilation solution. Diversitech provides a number of different downdraft tables and cartridge dust collectors for the safe removal of dusts due to grinding and deburring. Wet downdraft tables are recommended for the capture of combustible dusts.

Protecting Student Health

Educational institutions face a number of unique problems when providing students with a safe and functional workspace where they can learn. Because schools often need to fit a number of training students into a small workspace, capturing contaminants at source is essential to maintain indoor air quality. As the number of students per class often fluctuates, the ability to adapt to changing class sizes is required.

Additionally, educational institutions often need to be mindful of conserving energy to keep costs down. Recycling filtered air back into the facility prevents climate controlled or heated air from being ventilated outdoors.

Diversitech offers a number of air filtration options that work to protect student health and accommodate small workspaces while helping educational institutions save on energy costs. Our line of dust collectors, extraction arms, portable fume extractors and downdraft tables are excellent for capturing welding smoke, dust and fume at source.

Designed specifically for the vocational market, our line of welding booths can be arranged to maximize floor space while allowing students to weld and grind in a safe enclosed space. Our mobile welding trailer can accommodate multiple welding stations and be custom outfitted with different equipment and fume extractors. We also offers a mobile welding lab inside a trailer that accommodates multiple welding stations and can be custom outfitted based on your school’s requirements.