Slacan Industries Case Study

Overview

Founded in Hamilton, Ontario in 1912, Slacan Industries is one of Canada’s largest manufacturers of electrical transmission, distribution and communications hardware. Serving mainly the electrical utility and communication markets, the company provides a complete line of distribution, EHV transmission and other poleline hardware. Known for their “legendary quality”, Slacan manufactures some of the most durable and long-lasting hardware in North America.

The Problem

Using steel shot blasting in their manufacturing process, Slacan had some safety concerns about the combustibility of the dust generated in their plant. A type of abrasive blasting process, steel shot blasting propels steel parts onto a material’s surface to clean and remove oxides and other debris. Slacan’s 14 cubic foot Wheelabrator and 6 cubic foot Cardinal shot blast launches raw, normalized and annealed steel that ranged from plate, threaded, forged and cast steel parts.

The application created hazardous dusts that not only posed inhalation hazards, but were also highly combustible. Fire and explosion presented the most urgent risk to workers, but chronic diseases were also a concern. Long-term exposure to metal dust is known to cause conditions such as silicosis, bronchitis, respiratory damage and even lung cancer.

Slacan knew they needed to provide better safeguards for their employees as well as their facility. The dry dust system they had previously installed in their plant failed to mitigate the risks of fire and explosion. The company was looking for a solution that not only gave their building and employees the fullest protections possible but also ensured that the factory remained up to code.

The Solution

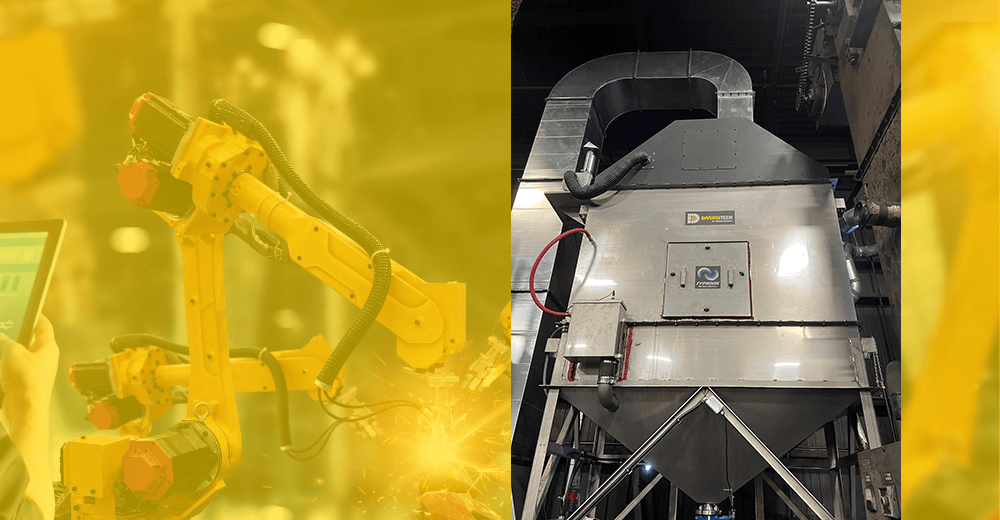

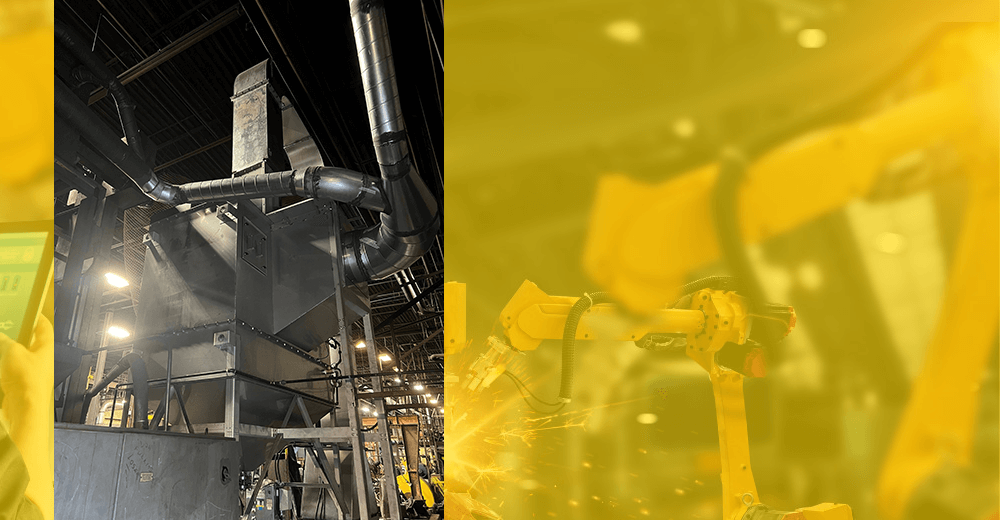

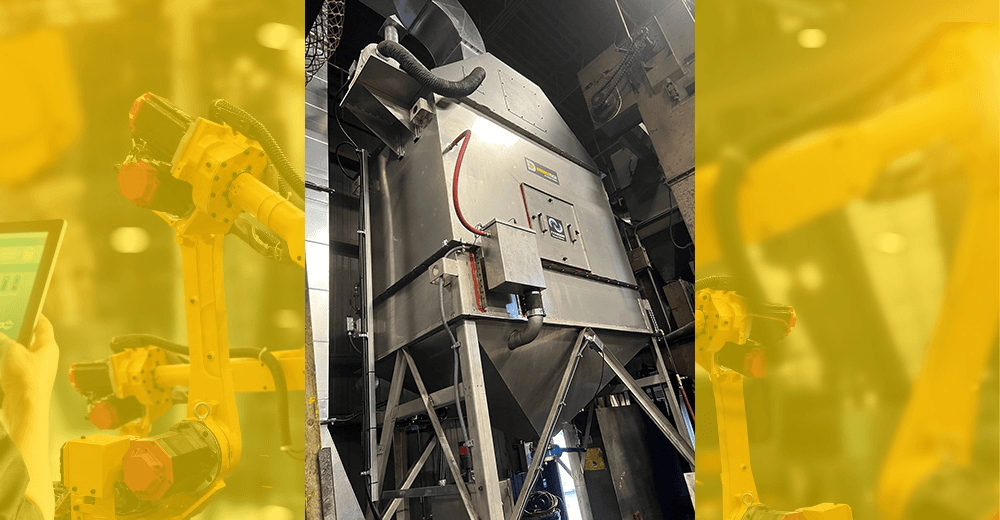

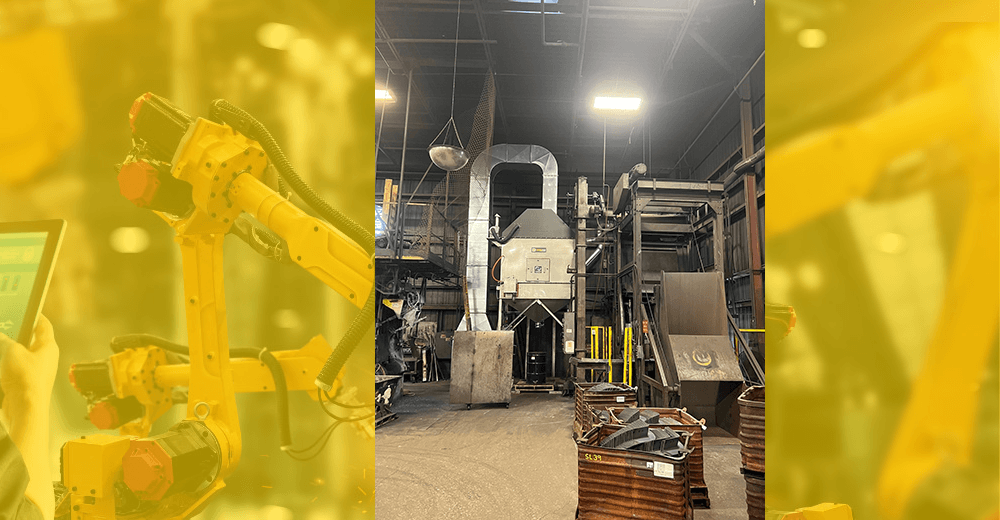

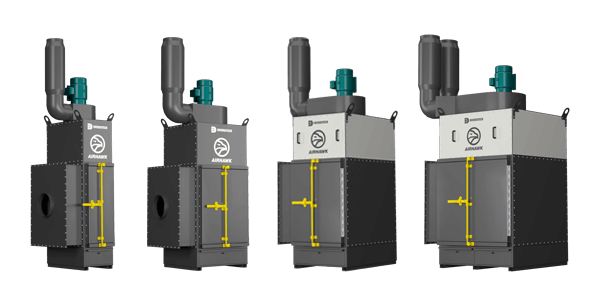

Slacan called Diversitech to help address their air quality concerns. To adequately contain the combustible dust in Slacan’s factory, Diversitech recommended a custom installation of their Typhoon Central Wet Dust Collector. With high efficiency filtration capabilities, the Typhoon had the ability to safely capture explosive dusts while requiring minimal maintenance.

Diversitech wired the Typhoon unit directly to Slacan’s 14 cubic foot Wheelabrator and 6 cubic foot Cardinal shot blast so that the collector would turn on automatically with startup. As requested by Slacan, Diversitech constructed the unit with legs so that the pan and hopper could be drained directly into a steel drum using a ball valve for waste pickup. Simplifying maintenance further, the Typhoon’s bay door allowed technicians to easily power wash the interior and check the condition of the filter.

The Result

With their new Typhoon Central Wet Dust Collector, Slacan has noticed an improvement in working conditions across the board. The most noticeable benefit has been in the time saved each month on maintenance. In the past, their old unit had required roughly three hours each day in cleaning and preventative maintenance. Now, with their new Typhoon, they spend just 10 minutes each day on cleaning and only have to dedicate time once a month for preventative maintenance. As a result, the company enjoys considerable savings in manpower allocation, water usage and filter changes.

Most importantly, Slacan workers benefit from cleaner indoor air in the factory. Almost no dust or debris escapes out of the final filters and into the plant. The building and the employees remain safe from the risk of catastrophic harm from combustible dust.