Lead-free Solder

Soldering Fumes are Unbreathable

Fumes created during soldering can cause irritation to nose, throat and respiratory organs. Extended or repeated exposure to soldering fumes may lead to more serious health conditions.

What is Solder?

Solder is used by assembly workers in many industries to make electrical connections and to seal copper pipe during plumbing installations. It is typically available in a wire form made from various metals with a core of flux on the inside. Soldering is accomplished by heating the two items to be connected with a soldering iron, and touching the heated points with the solder, which melts, flows, and solidifies to form a permanent connection. Flux helps to prevent oxidation during the soldering process.

Why are Solder Fumes Considered a Health Hazard?

When solder wire is heated, fumes are produced that contain various chemicals. Breathing of these fumes can cause asthma or aggravate existing respiratory conditions. The fumes can also cause irritation of the upper respiratory tract, eyes and skin. Hand soldering offers greater risk because the worker’s head is likely to be in close contact to the fume source. Co-workers in the vicinity may also be at risk of exposure.

What are Some Warning Signs?

Early symptoms of fume exposure can include:

- Watering, irritated eyes

- Runny or stuffy nose

- Sore throat

- Coughing, wheezing

- Chest tightness, breathlessness

Who Can Be Affected?

Workers performing the following tasks and processes are potentially exposed to solder flux fumes:

- Electronic and electrical assembly and rework

- Repair of telecommunications equipment, HVAC units, and domestic appliances

- Desoldering (common in recycling)

- Plumbers working with copper piping

How Can I Protect Myself?

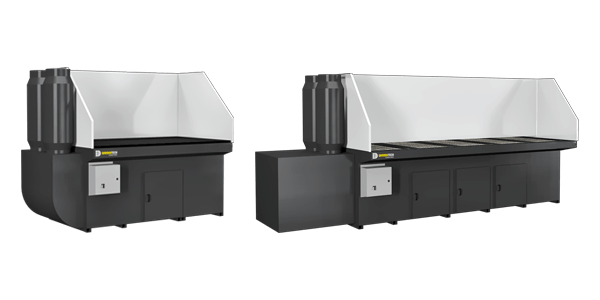

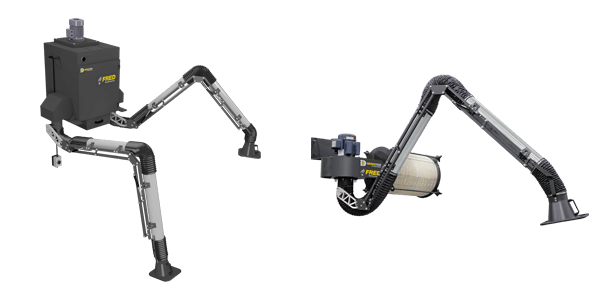

The best way to control exposure to solder flux fumes, as well as lead fumes, is to use a capture-at-source exhaust and filtration system. This works like a vacuum cleaner to remove fumes at the point where they are created and exhaust them outside or through a special filtration system. Downdraft tables and fume extraction arms offer capture at source ventilation.