Welding Fumes

Welding Fumes are Unbreathable

Welding practices produces smoke, dust and fumes that are highly toxic when inhaled. As metal is heated above boiling point, it creates vapors that condense into very fine, solid particulate. These microscopic particles can easily pass through the nasal cavities and into the lungs, damaging worker health. The resulting health conditions vary and depend on the following factors:

- Total weld fume composition

- The type of welding being done

- The length of time of exposure

- The work environment and protection used

Composed of a mixture of metallic oxides, silicates and fluorides, the exact makeup of weld fume is determined by a number of factors. The type of metal being welded, the paint and coatings on the metal, shielding gases and airborne contaminants such as degreasers and cleansers all affect weld fume composition.

Health Risks

The type and severity of health conditions that result from welding fume exposure depend directly on the type of metal being welded. Welding galvanized steel, for example, can lead to metal fume fever. Characterized by flu-like symptoms such as fever, chills, weakness, fatigue, aches, nausea and metallic taste, metal fume fever usually lasts no more than a day.

But welders are at risk of developing much more serious conditions, especially with long-term exposure. The welding of stainless and galvanized steel produces the highly toxic byproduct hexavalent chromium. Recognized by the Occupational Safety & Health Administration (OSHA) as a carcinogen, exposure to hexavalent chromium can lead to a number of serious conditions including lung and nasal cancers as well as liver and kidney failure.

Other carcinogenic metals that may be found in weld fume include nickel, beryllium, arsenic and cadmium. High levels of cadmium can be fatal, even after just initial exposure.

But cancer is just one of the conditions that can result from inhaling weld fume long-term. Workers also are at risk of developing:

- Bronchitis

- Asthma

- Pneumonia

- Emphysema

- Pneumoconiosis

- Decreased lung capacity

- Silicosis

- Siderosis

- Heart Disease

- Skin Disease

- Chronic gastritis (inflammation of the stomach)

- Gastroduodenitis (inflammation of the stomach or small intestine)

- Ulcers of the stomach and small intestine

- Reproductive problems

Welding practices also produce a number of gases that pose an immediate threat to worker health. Helium, argon and carbon dioxide can displace oxygen in the room and lead to suffocation when welding in an enclosed area. Carbon monoxide may also form, putting welders at risk of asphyxiation

Fire and Explosion Risks

Welding also has the potential to generate combustible gases and dusts. Whether or not the dusts produced are flammable depends directly on the type of metal being welded. Carbon steel and aluminum are two metals that can be highly explosive under certain conditions.

Failure to properly capture these combustibles can lead to worker injury and death as well as destruction of company property.

How Can I Protect Myself?

Effective Ventilation

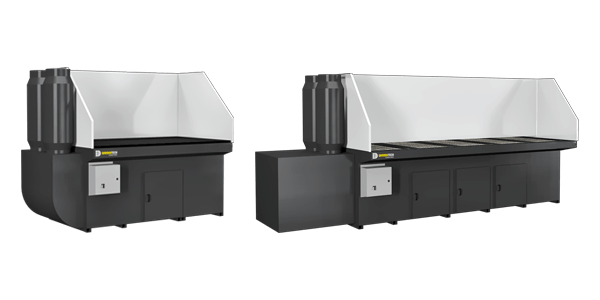

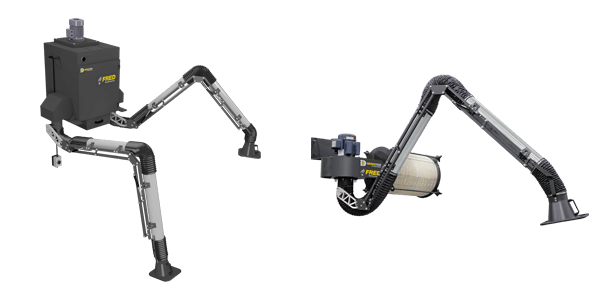

The most efficient method to control weld fumes is to capture them at source. Capture-at-source ventilation such as portable fume extractors and downdraft tables draw the fumes in and away from the operators’ breathing zones to protect workers. Indoor air remains uncontaminated.

If capture-at-source is not feasible, employers can opt for an ambient air cleaning solution. These systems are often used when welders work in wide open spaces or on large pieces. Used alongside capture-at-source, ambient air filtration helps create an even cleaner air facility.

But purchasing effective ventilation equipment is only part of the equation. A number of factors go into the proper use of air filtration equipment, including:

- The training of operators on safe use and capture zones

- The regular cleaning and servicing of filters

- The correct filter type for the materials being worked on

- Sufficient face velocity to draw in smoke and fumes created by the application

Failure to implement the above recommendations may result in an ineffective capture of airborne contaminants.

Understanding Your Specific Application and Safety Requirements

The type of filtration equipment you choose depends on the materials worked on as well as your unique work situation. To properly asses your specific requirements, you’ll need to determine:

- Whether or not your welders work in a confined space with little ventilation

- The type of metals being welded

- If the work pieces are clean, painted, coated or covered with degreasing solvent

- Whether or not your filtration equipment is working properly

- If there are any prevalent air streams that you can leverage

- Whether or not your welders need to use a respirator