Diversitech, a global leader in air polution solutions, offers a vast selection of product types for use with various industrial applications. Discover our most popular products.

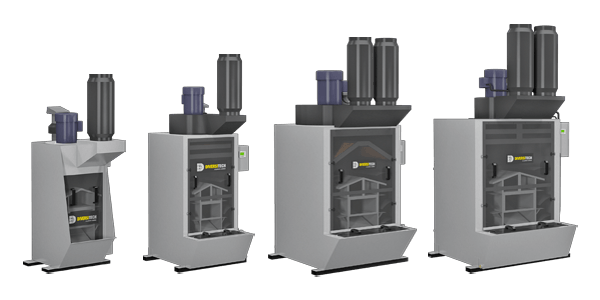

SwiftStock products represent the 6 base models of our most popular fume and dust collection products. These products are available for immediate order and will ship within one business day.

Diversitech, a global leader in air polution solutions, offers a vast selection of Portable Fume Extractors for use with various industrial applications such as welding, soldering, painting and more. Discover our most popular products.

Wall-mounted Fume Extractors allow fabrication shops to cost effectively mount air cleaners on a wall, column or ceiling mount configuration, saving valuable floor space for employees and production equipment in confined floor space environments.

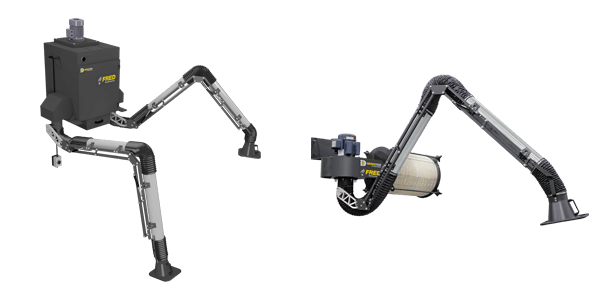

With Diversitech’s line of exhaust Arms & Blowers, you can create a capture-at-source solution that adequately protects your workers and helps you stay OSHA-compliant, ensuring that your working environment is clean and safe.

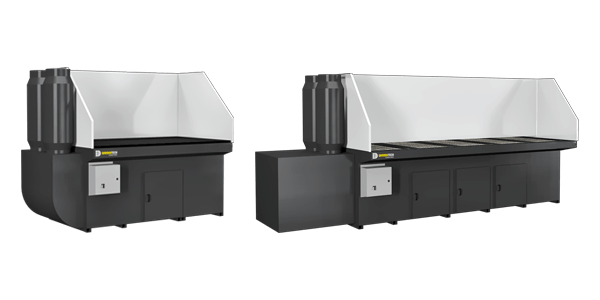

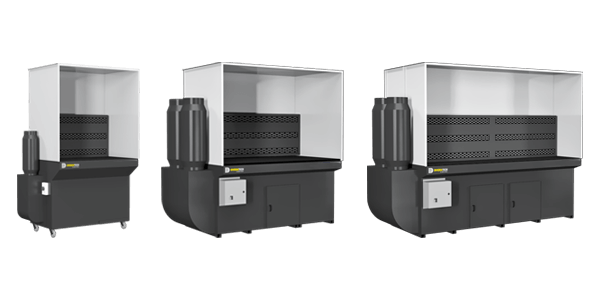

Installing high quality Downdraft Tables as part of your production process will provide workers with a safe environment to accomplish their work, while ensuring a high level of quality and performance to which you’ve grown accustomed.

Downdraft Booths, Dust Booths or Backdraft Tables are workstations with built-in ventilation to capture and filter dust, smoke, and fumes and then return clean air to a shop floor which can eliminate costly exhaust and air makeup systems.

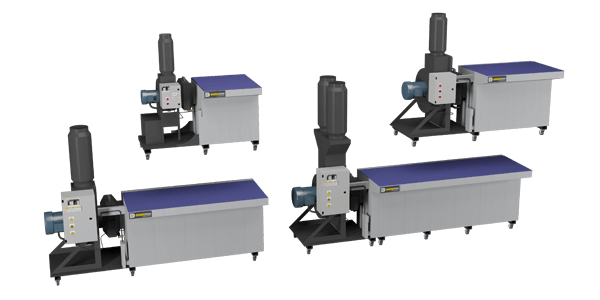

Ducted Downdraft Tables are a flexible and customizable workstation that can be connected to any central dust or fume collection system. Un-filtered downdraft tables can be custom fabricated based on your specific application requirements

Wet Downdraft Tables provide an efficient means of capturing and arresting combustible dusts. Diversitech produces all wet collectors in stainless steel to avoid rust and corrosion.

Wet Dust Collectors provide a safe and efficient means of capturing and arresting combustible dust and can be connected to different types of capture devices.

Cartridge Dust Collectors are versatile machines capable of collecting dust and smoke from multiple sources throughout a factory. They can either be situated indoors or outdoors and use duct work to capture and convey particulate.

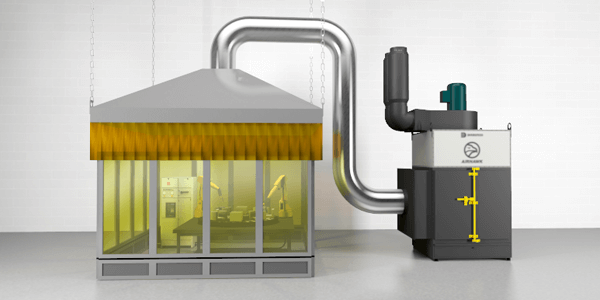

Diversitech's Environmental Booths provide the only effective method of eliminating airborne dust at the source when welding, grinding, spray-painting and sanding on large dimension parts and assemblies.

Welding generates gases and fumes that are dangerous to your health, and you must take measures to capture and filter fumes at the source to protect you. Our Welding Booths are also designed to filter airborne dust from grinding.

Diversitech’s Robotic Cell Fume Extractors collect fumes at the source, above the welding cell using an overhead canopy hood to ensure the fumes are contained and filtered effectively.

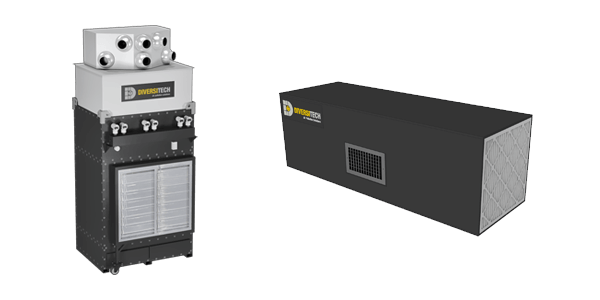

Diversitech's Ambient Air Cleaners consist of cost-effective disposable filter air cleaners and self-cleaning filtration systems, and excel at extracting welding fumes, dust and airborne oil mist from production shops and welding bays.

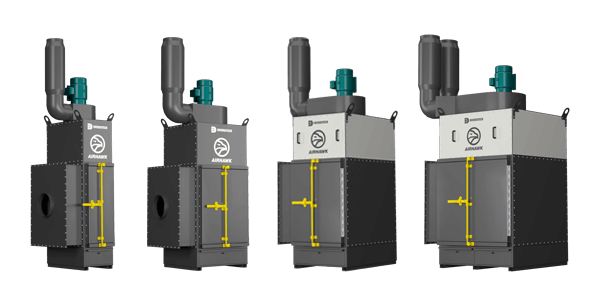

Airborne oil mist can damage CNC Machines and electronics, and can result in slippery, dangerous floors. They can also damage the lungs of machinists and operators in your machine shop. Explore our quality Oil Mist & VOC Collectors.